Optimal systems for wastewater treatment in Danish Industrial Park: HYPERDIVE® and E-FLEX®

Fluidmechanically optimized INVENT mixing and aeration systems have been providing reliable wastewater treatment in an industrial park on the Danish island of Zealand since 2016.

Ten HYPERDIVE®-Mixing and Aeration Systems and two E-FLEX®-Aeration Systems have been in service in the “Stigsnæs Industripark” reliably and maintenance-free since 2016. The industrial park is located on the west coast of Zealand, Denmark’s largest island. One of Denmark’s most important industrial ports is located in the immediate vicinity. An oil refinery operated here until 1997. The oil port with oil terminal, however, is still in operation, – as are the many large storage tanks. Wastewater treatment and purification are particularly important in this environment. That is why there was no question about building a dedicated wastewater treatment plant at the time the industrial park was being planned. Operators at the time relied on high-quality plant and mechanical engineering technology like the technology offered by INVENT.

The ten HYPERDIVE®-Mixing and Aeration Systems operate in two round sludge basins to keep the content in motion. The HYPERDIVE® is a fluid mechanically optimized mixing and aeration system consisting of a robust hyperboloid mixer- body with cage design, an aeration ring, a foot construction, a submersible drive and a process air hose, specifically designed for heavy-duty use in industrial and municipal wastewater treatment plants. It is a combination of efficient oxygen supply and optimized mixing of the basin content, ensuring that as little sediment as possible is formed on the bottom.

The high-quality systems are designed for long service life

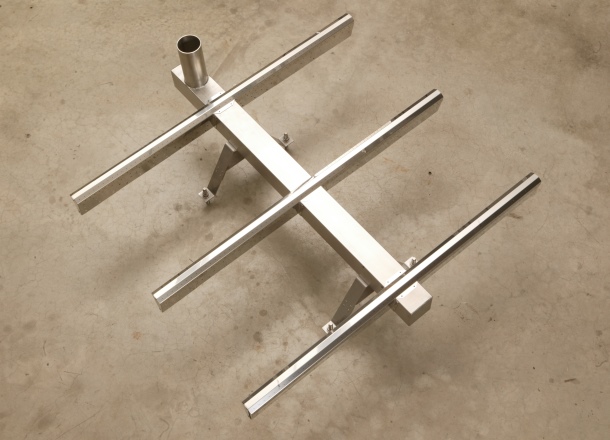

The hyperboloid mixer-body is made of high-quality fiber-reinforced plastic, making it both lightweight and non-corrosive. The cage with its specially molded stainless steel base construction provides the required weight, allowing the construction to be placed on stable footing. The base is also coated with epoxy resin.

Only energy-saving and robust motors, gears with reinforced bearings and seals from reputable manufacturers are used for the moving parts. The supply air hose is connected to a blower station located outside the basin, ensuring the supply of air or oxygen to the HYPERDIVE®-Mixing and Aeration System.

The two rectangular E-FLEX® membrane aeration modules are placed in a smaller, round aeration tank. The maintenance-free systems are made of stainless steel and other wastewater-resistant, environmentally friendly, resource-efficient and recyclable materials, facilitating the supply of fresh air so that the purification bacteria that are “active” in the wastewater receive sufficient oxygen.

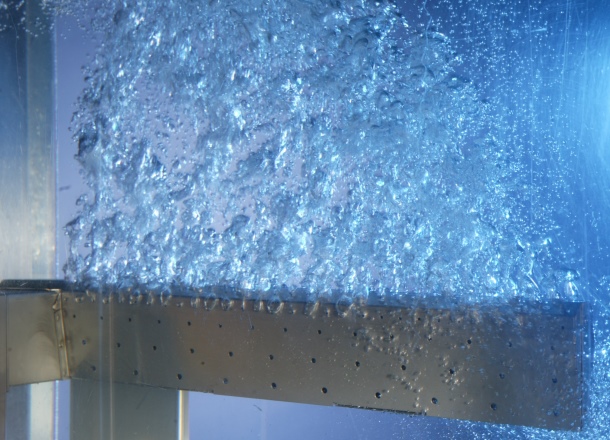

The E-FLEX®-Aeration System is designed to inject large volumes of oxygen into the wastewater with the least amount of energy possible. Air bubbles with optimum bubble sizes are generated on the flexible membranes to achieve this task. This technology incorporates a wealth of fluid mechanical knowledge from INVENT’s research laboratories as well as a great know-how in computational fluid dynamics (CFD) from the THINK Fluid Dynamix® experts

The fact that the systems have performed so reliably and maintenance-free up until now was to be expected, given that even the most heavily stressed components were designed for a service life of at least 100,000 hours.