Efficient homogenization and recirculation in sludge digesters to maximize gas yield.

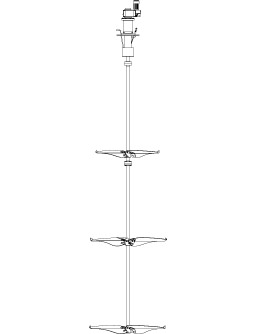

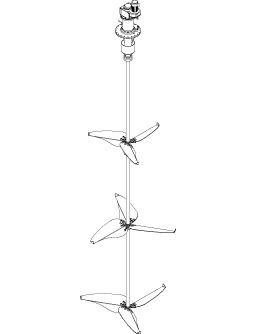

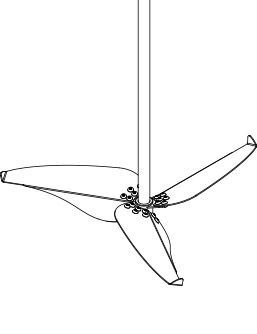

CYBERSLUDGE®-Mixer

Product Information

To guarantee an optimum process control in sludge digesters, INVENT developed the CYBERSLUDGE®-Mixer. It combines a fluid mechanically optimized agitator design, rugged construction for the highest requirements and many years of expertise in explosion protection (ATEX).

| Designation | Value |

| Rated Capacity | 1,1 – 30 kW |

| Mixer Body Diameter | 500 – 3.000 mm |

| Rotation Speed | 15 – 52 rpm |

| Mixer Body Material | SS 316 |

| Shaft Length | ≤ 20 m |

| EX Zone Drive | 1 or 2 |

| Sealing (EX) | Water lock, special versions possible |

Bodum, Sweden

Plant: WWTP Bodum ARF, Sweden

Contractor: ATEK Avvattningsteknik AB

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Sludge Treatment (Mesophile Fermentation)

Scope of Delivery:

Estonia Dairy, Estonia

Plant: WWTP Estonia Dairy, Estonia

Contractor: R-Insenerid OÜ, Estonia

Type of Plant: Industrielles Abwasser – Milch Industrie

Start-up Year: 2022

Application:

- Mixing for anaerobic degradation

- Aeration for BOD/COD elimination in aerobic tanks

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

In our videos we introduce the INVENT mixing technology

Applications of the INVENT CYBERSLUDGE®-Mixer

Sludge digestion / mixing in digesters

Optimum process control in digesters depends on the quality and correct mixing, circulation and homogenization of the sludge. In addition, high demands are placed on structural safety and explosion-proof design (ATEX).