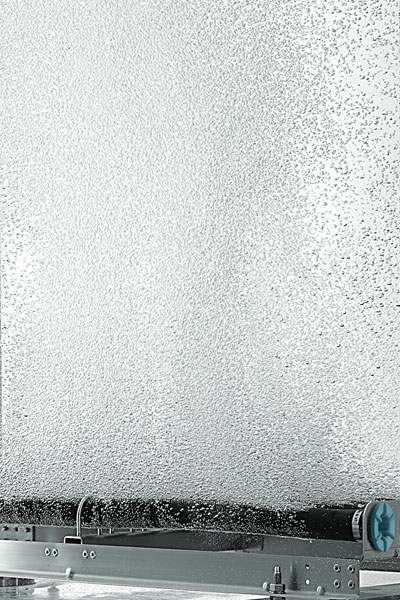

The fine-bubble E-FLEX®-Aeration System is characterized by a highly efficient oxygen transfer, a robust and low-maintenance design and flexible application options in municipal wastewater treatment.

E-FLEX®-Aeration System

Product Information

The requirements for a highly efficient, robust and versatile aeration system led to the development of the E-FLEX®-Aeration System.

The E-FLEX®-Aeration System has the following advantages and properties:

- Freely oscillating hose membranes ensure the highest possible oxygen transfer efficiency through an extremely fine-bubble aeration pattern

- Robust construction

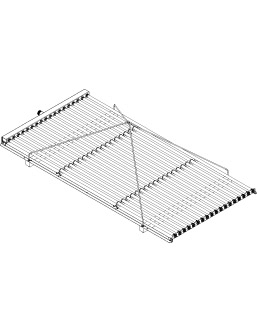

- By using a lifting kit and pre-assembled modules, installation is extremely quick and easy, even in filled basins

- The modular design enables flexible design and, if necessary, retrofitting of existing installations

- A large usable control range and a modular concept enable flexible operational management

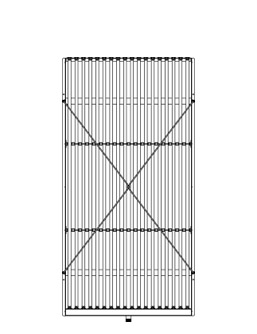

| Designation | Value |

| Air Volume | 50 – 215 Nm³/h/Module |

Membrane Material | EPDM or Silicone |

| Frame Material | 1.4301 or1.4571 |

| Membranes per Module | 12 / 18 |

| Active Membrane Area | 3,3 or 5 m²/Module |

| Bubble Diameter | 1 – 3 mm |

| Pressure Drop | 60 – 90 mbar |

Morelia, Mexico

Plant: WWTP Morelia, Mexico

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2006

Application:

- Aeration for BOD elimination and nitrification

Scope of Delivery:

Steegenwiesen, Germany

Plant: WWTP Stollberg-Steegenwiesen, Germany

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 1997

Application:

- Aeration for BOD elimination and nitrification

Scope of Delivery:

Geminis Zibatá, Mexico

Plant: WWTP Geminis Zibatá, Mexico

Type of Plant: Municipal Wastewater Treamtment Plant

Start-up Year: 2016

Application:

- Aeration for BOD elimination and nitrification

- Flow acceleration and homogenization in an anoxic/aerobic circulation basin

- Suspension and Homogenization for denitrification in anoxic basins

- Sludge aeration

Scope of Delivery:

Příbram, Czech Republic

Plant: WWTP Příbram, Czech Republic

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2006/2007

Application:

- Aeration for BOD elimination and nitrification

- Suspension and homogenization for denitrification in anoxic tanks and degassing basins

Scope of Delivery:

Fersinsa, Mexico

Plant: WWTP Fersinsa Gist-Brocades, Mexico

Type of Plant: Industrial Wastewater Treatment

Start-up Year: 2002

Applications:

- Aeration for BOD elimination and nitrification

Scope of Delivery:

- 292 E-FLEX®-Aeration Systems

- 6 HYPERCLASSIC®-Mixers

- Engineering & Design

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

Aeration Systems for Modern Wastewater Treatment

Applications of the INVENT E-FLEX®– Aeration System

BOD/COD degradation

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination.

The agitation and gassing system acts as a permanent aeration system for biological carbon degradation in aeration tanks. We can react flexibly to fluctuations in freight. The simultaneous circulation by the agitator ensures a homogeneous and deposit-free mixing even with low air supply in the activated sludge tank.

Fakultative aeration

In nitrification stages, the stirring and aeration system serves as a permanent aerator. If (seasonal) process changes in the activated sludge tank require a temporary changeover from nitrification to denitrification (swing zone), it is possible to run in pure agitation mode without aeration. A change between operation with ventilation and without ventilation is possible at any time.

Membrane bioreactor (MBR)

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination Continuous cleaning of the membrane surface to limit the cover layer thickness.