Rugged disc aerator for highly efficient air intake in activated sludge applications.

iDISC®-Membrane Diffuser

Product Information

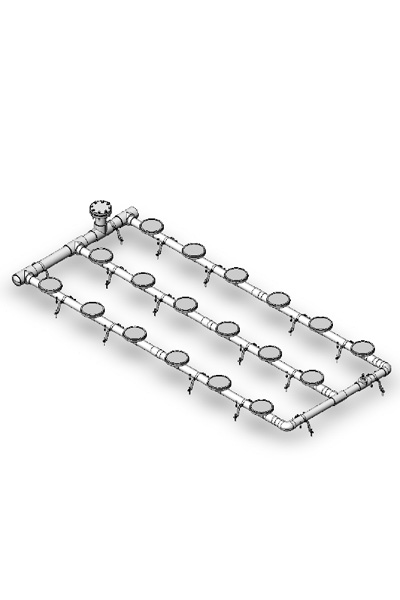

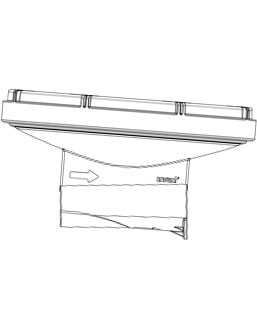

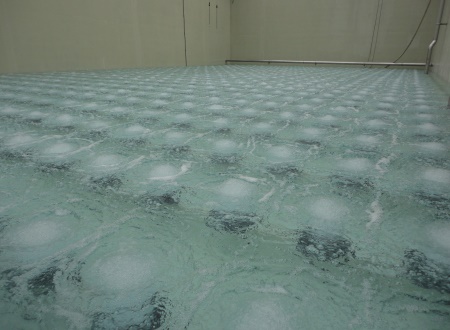

The iDISC®-Membrane Diffuser was developed and optimized for oxygen transfer in activation basins for municipal and industrial wastewater treatment plants. The aeration system is installed on the bottom of the basin and generates the maximum possible oxygen transfer values as a result of a fine, uniform bubble pattern.

Use of the iDISC®-Membrane Diffuser has the following benefits:

- Mechanically rugged design guarantees many years of use even in deep basins

- Optimized construction based on fluid mechanics ensures the best possible bubble pattern even in combination with additional equipment in the basin

- Large usable control range allow flexible operation management

- High oxygen utilization results in excellent energy efficiency

- In-depth process design to ensure oxygen requirement for the specified load cases with optimal geometric configuration

| Designation | Value |

| Air Amount | 1 – 8 Nm³/h/Module |

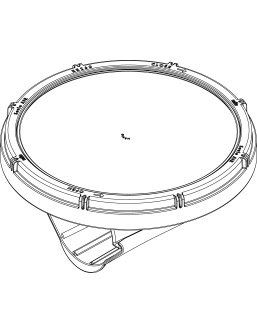

Membrane Diameter | 237 mm |

| Active Membrane Surface | 0,044 m² |

| Bubble Diameter | 1 – 3 mm |

| Pressure Drop | 22 – 43 mbar |

Westdale, Australia

Plant: WWTP Westdale, Australia

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- iSBR

Scope of Delivery:

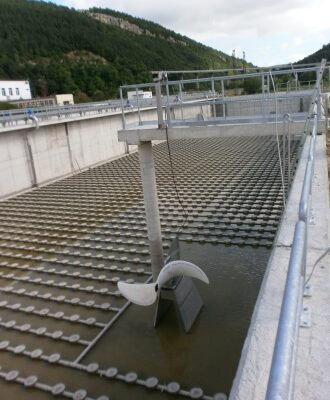

Gabrovo, Bulgaria

Plant: Gabrovo, Bulgaria

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2013

Application:

- Intermittent aeration for nitrification/carbon removal

- Stirring and aeration in anoxic/aerobic tanks

Scope of Delivery:

Kronshtadt, Russia

Plant: WWTP Kronshtadt, St. Petersburg, Russia

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2014

Application:

- Aeration in activated sludge basins

- Stirring in anoxic-aerobic activated sludge tanks

Scope of Delivery:

Kazanlak, Bulgaria

Plant: WWTP Kazanlak, Bulgaria

Contractor: Environment Commerce CZ

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2013

Application:

- Agitation and aeration for BOD elimination

- Nitrification/denitrification

Scope of Delivery:

Pliva, Croatia

Plant: WWTP Pliva, Croatia

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2013

Application:

- Aeration for BOD elimination

- Suspension, homogenization and balancing in anoxic tanks and selector tanks

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

Aeration Systems for Modern Wastewater Treatment

Applications of the INVENT iDISC®-Membrane Diffuser

BOD or COD degradation

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination.

The agitation and gassing system acts as a permanent aeration system for biological carbon degradation in aeration tanks. We can react flexibly to fluctuations in freight. The simultaneous circulation by the agitator ensures a homogeneous and deposit-free mixing even with low air supply in the activated sludge tank.

Fakultative aeration

In nitrification stages, the stirring and aeration system serves as a permanent aerator. If (seasonal) process changes in the activated sludge tank require a temporary changeover from nitrification to denitrification (swing zone), it is possible to run in pure agitation mode without aeration. A change between operation with ventilation and without ventilation is possible at any time.

Membrane Bioreactor (MBR)

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination Continuous cleaning of the membrane surface to limit the cover layer thickness.