The requirements for wastewater treatment in the food and beverage industry can vary greatly depending on the production and load, as well as seasonal or campaign operations. There is not only very special production water from the respective industry, but mostly also cooling, cleaning and sanitary waste water from the factories. The partial flows can be very different in terms of volume flow and contamination parameters. In addition, specific optimization approaches with regard to water circuits and process requirements or the type of discharge flow into the planning and dimensioning of industrial wastewater treatment.

Food and beverage industry

INVENT solutions for

Food and beverage industry

The following sectors belong to the field of waste water treatment in the food industry:

- sugar and starch factories

- Vegetable and fruit processing industry

- milk processing industry

- Slaughterhouses and meat or fish processing industry

- Edible oil and fat production

- Beverage production, breweries, winemaking

- distilleries and yeast industry

Challenges for machine technology

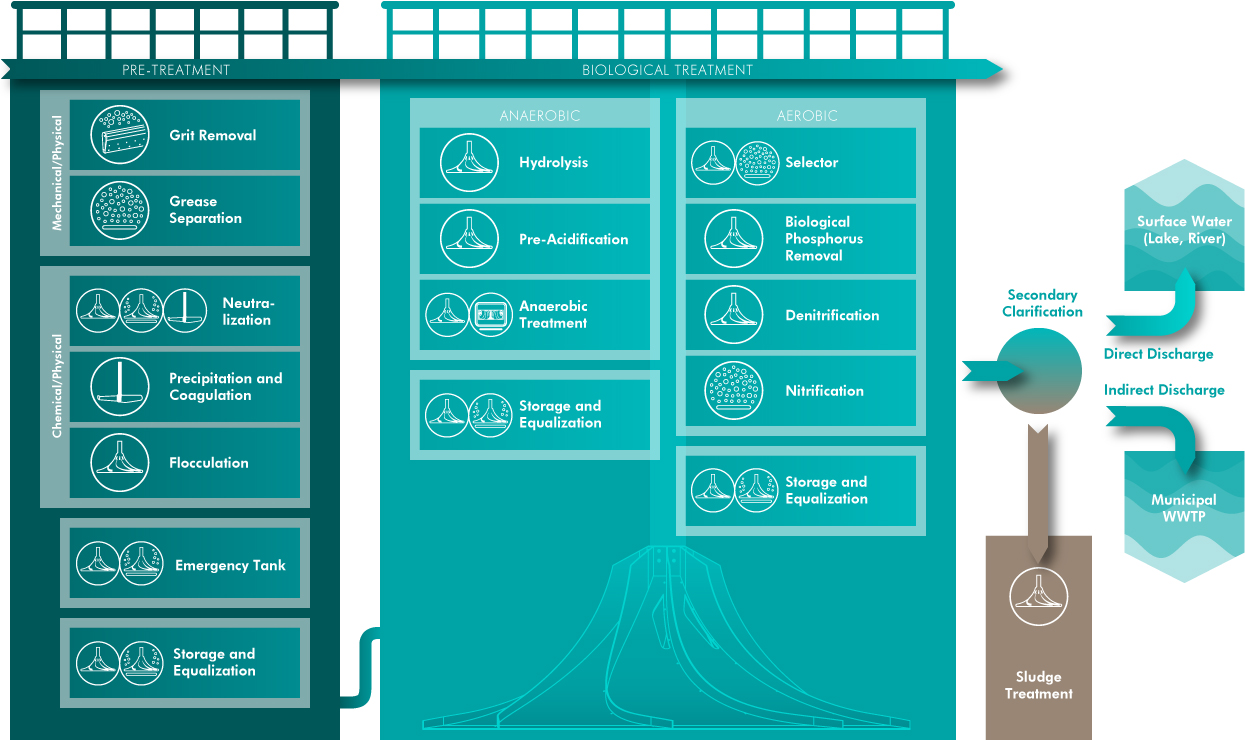

The wastewater composition depends on the branch and the individual production line. Usually, a biological stage for waste water treatment is used after the individually required preliminary treatment. The choice of the appropriate procedure, aerobic, anaerobic or a combination of both process stages, depends heavily on the wastewater composition, temperature, load and also volume flows.

For example, in the case of waste water containing fat, such as in oil, milk and meat processing plants, a fat separation before the biological process makes sense. Fats and oils, just like surfactants from rinsing and washing water, have a negative effect on the substance transport during aeration in waste water and can damage membrane aerators. Another challenge lies in the favored formation of bulking sludge or sludge that is difficult to settle. These can be decisively positively influenced by the choice of process and operating parameters, also by choosing the right stirring and aeration system.

In addition to other ingredients, an increased process temperature must be taken into account when choosing the machine technology in order to ensure a long-term and operationally stable process.

Regardless of whether wastewater contains corrosive, abrasive or greasy/oily components or has high temperatures, INVENT can offer a tailor-made, robust and efficient solution thanks to the wide range of machine technology and many years of experience in various industrial applications.

Our diagram gives a general overview of typical process steps in the wastewater treatment of beverage and food processing plants.

INVENT offers you mixing technology as well as mixing and aeration systems optimized for the respective mixing task and the process. Contact us here.

- Grit Removal

- Grease Separation

- Neutralization

- Precipitation and Coagulation

- Flocculation

- Emergency Tank

- Storage and Equilization

- Hydrolysis

- Pre-Acidification

- Anaerobic Treatment

- Selector

- Denitrification

- Nitrification

Settling contaminants such as sand not only impair the cleaning performance of a sewage treatment plant, but also cause serious damage to the equipment. The aeration of the sand trap accelerates and improves the settling behavior of mineral solids and thus prevents operational disruptions.

The robust INVENT iCBA®-Aeration System has been specially developed for harsh operating conditions. The durable stainless steel construction ensures long-term reliable gassing performance.

Grease separators separate fats and oils from waste water. The aeration in the fat separator also increases the difference in density and thus faster separation of the unwanted ingredients.

The robust INVENT iCBA®-Aeration System has been specially developed for harsh operating conditions. The durable stainless steel construction ensures long-term reliable gassing performance. Membrane aeration systems are not suitable in this case due to the composition of the wastewater.

INVENT CYBERPITCH®-Mixer

INVENT HYPERCLASSIC®-Mixer

So that the wastewater can be discharged into public sewage systems or bodies of water, it must have a pH value between 6.5 and 9. Acids or bases are added for neutralization.

The INVENT CYBERPITCH®-Mixer with its robust design made of high-quality stainless steel is ideally suited for this thanks to its flow-optimized agitator blade shape and the design with regard to turbulent mixing.

The INVENT HYPERCLASSIC®-Mixer is used for neutralization when energy-efficient mixing of the tank contents is required.

INVENT iBC-MIX®-Tote Tank Mixer

In addition to setting an optimal pH value, the selection of a suitable stirrer is also essential for a successful precipitation reaction. For the destabilization of the colloidal state, a high energy input and rapid mixing between the precipitating agent and the colloid is required to form microflocs.

The INVENT iBC-MIX®-Tote Tank Mixer with an included traverse is used for processing and storage in lattice tanks, which suspends the heterogeneous mixture of substances with little energy consumption.

INVENT HYPERCLASSIC®-Mixer

When conditioning the water, chemicals are added, which should be distributed as quickly and homogeneously as possible in the tank.

The INVENT HYPERCLASSIC®-Mixer has low shear forces due to its hyperboloidal agitator body shape and low speeds and at the same time ensures complete mixing of the container.

INVENT HYPERCLASSIC®-Mixer

In hydrolysis, complex macromolecules such as carbohydrates, proteins and fats are broken down into shorter organic compounds with the help of enzymes that act as biological catalysts.

The INVENT HYPERCLASSIC®-Mixer impresses above all with its low-shear energy input and at the same time offers optimal homogenization of the tank contents. In addition, the flow speed on the water surface is reduced to such an extent that no oxygen is introduced.

INVENT HYPERCLASSIC®-Mixer

A sufficient initial acidification of the dissolved polymers to form short-chain organic acids is decisive for a stable and efficient process in anaerobic wastewater treatment and ultimately a high methane yield.

Since this process is carried out by anaerobic bacteria, it is essential to avoid oxygenation, for example via the water surface.

The INVENT HYPERCLASSIC®-Mixer is installed near the bottom and generates a strong radial bottom flow. Since the speed at the water surface has reduced to such an extent that oxygen entry is effectively prevented, the INVENT HYPERCLASSIC®-Mixer is particularly suitable for this agitating task. In addition, thanks to the high pumping capacity, it ensures that all of the wastewater is thoroughly mixed, thereby ensuring efficient utilization of the entire reactor.

INVENT HYPERCLASSIC®-Mixer

Anaerobic processes play an important role in many industrial and municipal wastewater treatment plants. In the process, organic compounds are fermented in the absence of oxygen and, via intermediate stages, methane, among other things, is produced as the end product.

If mechanical mixing is required for these processes, the INVENT HYPERCLASSIC®-Mixer represents an optimal solution. The agitator body is installed close to the ground and generates a strong radial bottom flow. In addition, thanks to its high pumping capacity, it ensures that the entire contents of the tank are thoroughly mixed and thus that the entire reactor is used efficiently.

Numerical flow simulation (CFD) is an important and reliable tool for checking the interaction of the building geometry (inlet and outlet situations, baffle plates, overflows, etc.) with the existing or planned installations. This allows the efficiency of the entire system to be evaluated under different load conditions. Possible weaknesses in the design, such as additional turbulence, which can generate an unplanned oxygen input, can be identified and optimized in good time.

INVENT HYPERCLASSIC®-Mixer

In denitrification it is crucial that the activated sludge is homogenized with the recirculation and feed stream. Oxygen entry at the water surface must be effectively avoided.

The INVENT HYPERCLASSIC®-Mixer was specially developed for this. It generates both a high pump volume flow and a strong, radially outward bottom flow. Activated sludge is transported upwards along the tank wall. At the water surface, the speed has reduced to such an extent that no oxygen can be introduced.

INVENT E-FLEX®-Aeration System

INVENT iDISC®-Membrane Diffuser

INVENT HYPERCLASSIC®-Mixing and Aeration System

The ammonium in the wastewater is oxidized to nitrate by bacteria using dissolved oxygen. This requires an energy-efficient ventilation system.

The modular E-FLEX®-Aeration System has a flat design close to the ground. An oscillating movement of the EPDM membranes results in a high bubble separation frequency and thus creates very small bubble sizes with a long residence time.

The E-FLEX®-Aeration System can be delivered so that it can be lifted out for installation and maintenance work in filled pools.

The system can be combined with the INVENT HYPERCLASSIC®-Mixer and is suitable for intermittent processes.

The INVENT iDISC®-Membrane Diffuser is predestined for this. It is a highly efficient, fine-bubble membrane aeration system that is suitable for a wide variety of pool geometries due to its modular design.

The system can be combined with the INVENT HYPERCLASSIC®-Mixer and is suitable for intermittent processes.

The INVENT TEX-FLEX®-Aeration System with its robust stainless steel construction and textile membrane is the right choice for aggressive media.

The INVENT HYPERCLASSIC®-Mixing and Aeration System offers real advantages, especially for industrial use. The purely mechanical ventilation system reliably ensures an efficient supply of oxygen with a constantly low pressure drop. In stirring mode, it ensures optimal mixing of the tank contents.