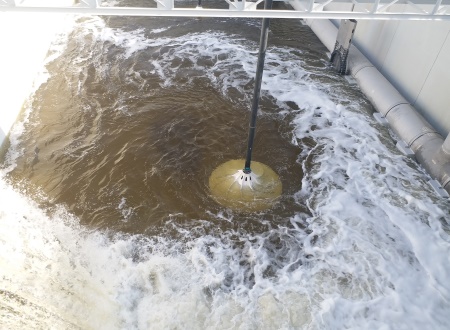

With this system, INVENT presents a highly flexible and rugged solution for fine-bubble aeration in municipal and industrial wastewater. Especially in difficult operating conditions, the exceptional properties of this system become increasingly valuable.

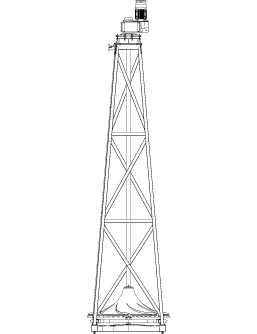

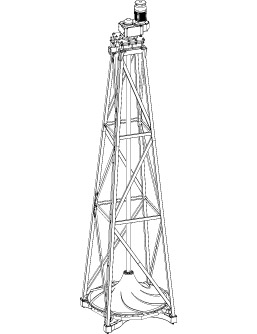

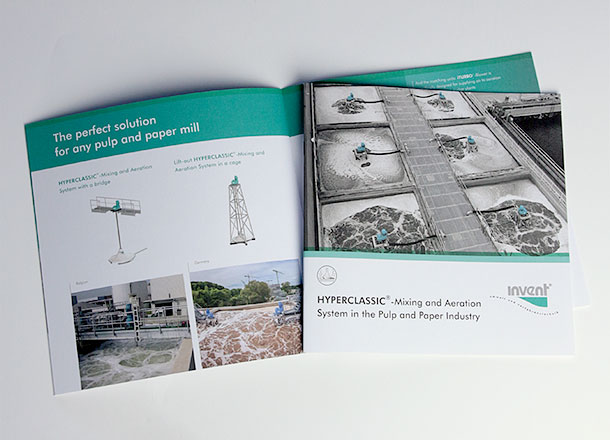

HYPERCLASSIC®-Mixing and Aeration System

Product Information

The HYPERCLASSIC®-Mixing and Aeration System was introduced in numerous process stages of municipal and industrial wastewater treatment plants over 25 years ago.

Uniquely, it combines the features of an agitator with those of an aerator, offering an extremely flexible range of operation and use:

- Agitation without aeration

- Fine bubble aeration with simultaneous homogeneous and deposit-free mixing

- Intermittent operation (e.g. SBR process, MAB)

The sophisticated design, the rugged construction and the mechanical aeration principle make this agitation and aeration system very versatile. As such, INVENT offers a reliable and variable solution for complex problems:

- High oxygen supply capacity even in difficult media (high TS, surface-active substances)

- No increase in pressure drop during operation in contrast to membrane aeration

- No aerosol formation

- Deposits are avoided in all operating stages

- Design in lift-out version available

- Materials are matched to operating conditions (temperature, pH, salinity, precipitation, etc.)

The HYPERCLASSIC®-Mixing and Aeration System is tailored to your requirements on a case-by-case basis and can be supplied in a number of versions – for installation on a bridge/tank cover, lift-out, submerged or floating.

| Designation | Value |

| Rated Capacity | 9,2 – 37 kW |

Efficiency Class | IE3 |

| Mixer Body Diameter | 2.000 / 2.500 mm |

| Rotation Direction | CW / CCW |

| Rotation Speed | 26 – 44 rpm |

| Mixer Body Material | GfK-PP |

| Cage Construction | Stainless Steel |

| Air Distributor | HPDE / Stainless Steel |

WWTP Aalen, Germany

Plant: WWTP Palm Papier Aalen, Germany

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2015

Application:

- Mixing and aeration for BOD/COD elimination in aerobic tanks

Scope of Delivery:

Aviko, Belgium

Plant: WWTP Aviko, Belgium

Type of Plant: Industrial Wastewater Treatment

Start-up Year: 2020

Application:

- Agitation and aeration for BOD/COD elimination in aerobic tanks

- Aeration for nitrification in aerobic tanks

Scope of Delivery:

Kimberly-Clark, UK

Plant: WWTP Kimberly-Clark, UK

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2006

Application:

- Mixing and aeration for COD elimination

Scope of Delivery:

Jebel Ali, UAE

Plant: WWTP Jebel Ali, UAE

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2009

Application:

- Aeration in the sand trap

- Stirring and homogenization in anoxic tanks

- Stirring and aeration in pre-aeration and aeration tanks

Scope of Delivery:

- Engineering & Design

- 20 HYPERDIVE®-Mixing and Aeration Systems

- 72 HYPERCLASSIC®-Mixing and Aeration Systems

- 32 HYPERCLASSIC®-Mixers

- 160 iCBA®-Aeration Systems

- Installation und Start-up

Varel, Deutschland

Plant: WWTP Varel, Germany

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2012-2019

Application:

- Mixing and aeration for BOD/COD elimination in aerobic tanks

Scope of Delivery:

Holit, Israel

Plant: WWTP Holit, Israel

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Mixing and aeration for BOD elimination, nitrification and denitrification in an SBR plant

- Clear water discharge in an SBR plant

- Suspension & homogenization in sludge storage tank

- Aerobic sludge digestion

Scope of Delivery:

Kriebethal, Germany

Plant: WWTP Kriebethal, Germany

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Mixing and aeration for BOD elimination

Scope of Delivery:

Jacksonville, USA

Plant: WWTP Jacksonville, Florida, USA

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2009

Application:

- BOD elimination, nitrification and denitrification in an SBR plant

Scope of Delivery:

- Engineering & Design

- 18 HYPERCLASSIC®-Mixing and Aeration Systems

- 8 iDEC®-SBR Decanting Systems

- 12 E-FLEX®-Aeration Systems

- Installation & Start-Up

Brunnenthal, Germany

Plant: WWTP Carl Macher, Brunnenthal, Germany

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2019/2020

Application:

- Mixing and aeration for BOD/COD elimination in an SBR plant

- Mixing and aeration for BOD/COD elimination in a lime trap

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

Product videos:

In these brochures we introduce our INVENT HYPERCLASSIC®-Mixing and Aeration System

Our aeration products

Applications of the INVENT HYPERCLASSIC®-Mixing and Aeration System

BOD or COD degradation

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination.

The HYPERCLASSIC®-Mixing and Aeration System acts as a permanent aeration system for biological carbon degradation in aeration tanks. It is possible to react flexibly to fluctuations in freight. The simultaneous circulation by the agitator ensures a homogeneous and deposit-free mixing even with low air supply in the activated sludge tank.

Nitrification

The HYPERCLASSIC®-Mixing and Aeration System ensures not only optimal mixing in the biological stage but also efficient oxygen supply during nitrification. The mechanical aeration method allows for a high oxygen transfer rate with minimal energy consumption and consistently low pressure loss.

SBR (Sequencing Batch Reactor)

In the SBR process, usually several cycles with different process phases are run through each day. Important boundary conditions for a well-functioning overall process include a rapid change between phases with oxygen supply and pure mixing operation, homogeneous mixing and flexible oxygen supply capacity with a wide working range.

In addition to the above boundary conditions, the HYPERCLASSIC®-Mixing and Aeration System additionally offers further advantages in the SBR process:

- In the case of strong seasonal freight fluctuations (food processing, tourism, etc.), a temporary shutdown is possible without any loss of quality of the components or functionality.

- Simple installation without complex internal structures in the tank – With the liftable version, maintenance can be carried out without emptying the tank.

Mixing and balancing with aeration

The influent loads to the biological treatment may exhibit significant fluctuations. In order to avoid having to size the treatment plant for peak loads, equalization tanks are constructed. Aeration prevents the wastewater from putrefying and developing unpleasant odors. The additional mixing capacity effectively prevents deposits in the tank.

The HYPERCLASSIC®-Mixing and Aeration System combines both tasks in one machine and can be perfectly adjusted to meet the specific requirements.

Fakultative aeration

In nitrification stages, the HYPERCLASSIC®-Mixing and Aeration System serves as a permanent aerator. If (seasonal) process changes in the activated sludge tank require a temporary changeover from nitrification to denitrification (swing zone), it is possible to run in pure agitation mode without aeration. A change between operation with and without aeration is possible at any time by using the HYPERCLASSIC®-Mixing and Aeration System.

Intermittend aeration

By utilizing intermittent aeration in conjunction with modern measurement, control, and regulation technology, the energy consumption of a wastewater treatment plant can be significantly reduced, leading to a stable operation with consistently low effluent values.

The HYPERCLASSIC®-Mixing and Aeration System is perfectly suited for intermittent operation as it can easily switch between aeration and mixing modes while ensuring complete mixing of the tank contents in all operational points. The risk of membrane clogging during switched off aeration is eliminated, making the HYPERCLASSIC®-Mixing and Aeration System a reliable and efficient choice for wastewater treatment processes.

Aerobic sludge stabilization

Activated sludge with high dry matter content forms a viscous, pseudoplastic medium. Due to the shear-thinning effect of the mixer body of the HYPERCLASSIC®-Mixing and Aeration System in aeration mode, there is a significantly better oxygen supply compared to membrane aerators. In addition, problems such as clogging of membranes, pressure increases and material aging due to high temperatures are no longer a problem by using the HYPERCLASSIC®-Mixing and Aeration System.

Deammonification

The HYPERCLASSIC®-Mixing and Aeration System can be utilized as a continuous aerator to convert ammonium in the sludge water into nitrite under aerobic conditions. When needed, it can easily switch to the mixing mode to increase the proportion of anaerobic bacteria in the Anammox process. Since Anammox bacteria are often sensitive to high or low oxygen concentrations, a highly flexible aerator is desirable. The HYPERCLASSIC®-Mixing and Aeration System provides this flexibility, allowing for optimal adaptation to the specific process requirements.

Pure oxygen aeration

The aeration or oxygen supply in the process can be carried out by using the HYPERCLASSIC®-Mixing and Aeration System with atmospheric oxygen or pure oxygen supply. During aeration with pure oxygen, the HYPERCLASSIC®-Mixing and Aeration System achieves high oxygen transfer efficiencies through the high specific mixing power input, thus minimizing the required pure oxygen and reducing operational costs.

Membrane Bioreactor (MBR)

By continuously cleaning the membrane surface and providing uniform aeration, the thickness of the fouling layer is limited. This is crucial for the activity of the biological microorganisms responsible for the degradation of organic substances in the wastewater. Additionally, uniform aeration can prevent deposits on the membrane surface, thereby minimizing maintenance costs. Furthermore, membrane bioreactors often have increased biomass concentrations, which do not lead to increased wear or maintenance requirements for the HYPERCLASSIC®-Mixing and Aeration System under such conditions.