100 ml to 10 l of water is consumed in the production of just one DIN A4 sheet of paper, depending on the raw material. Water is essential for all important process steps in paper production. It is intended as a suspension and transport medium for fibers and fillers, as a solvent for chemical additives and as a medium for forming the hydrogen bonds between the fibers. As such, paper in the sense we are familiar with cannot be produced without water. In the production process, water is recycled on a large scale. Wastewater is produced as excess recirculated water that is displaced by the fresh water used.

Pulp and paper industry

INVENT solutions for

Pulp and paper industry

Challenges for machine technology

Dealing with high calcium concentrations in paper production poses a challenge. The source of the increase in circulating water and waste water is calcium carbonate, which has been increasingly used in production as a cheap filler or coating pigment in recent years. This increases the calcium content in the waste paper, so that calcium is also increasingly being introduced into the wastewater via this secondary raw material. Too high concentrations can lead to operational problems with deposits and blockages in the waste water treatment. In addition, high temperatures and abrasive substances place high demands on the machine technology used, which is why know-how, quality and experience are essential for a successful project. INVENT has been successfully equipping wastewater treatment plants in the pulp and paper industry for more than 25 years, which makes us one of the leading experts in this field.

INVENT offers you mixing technology as well as mixing and aeration systems optimized for the respective mixing task and the process. Contact us here.

Product videos:

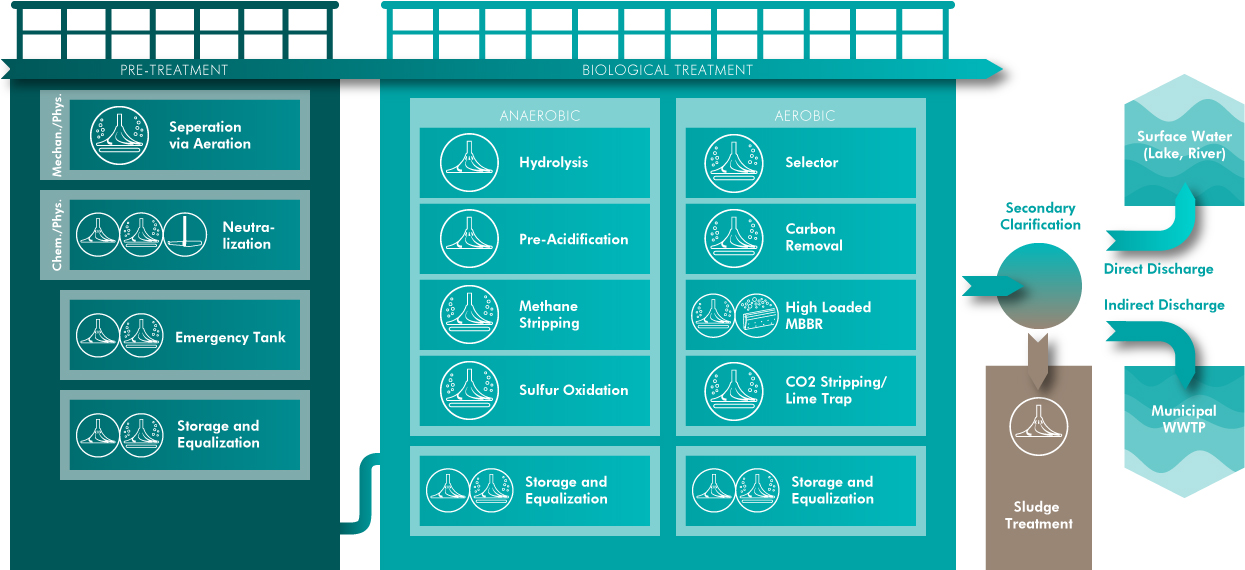

HYPERCLASSIC®-Mixing and Aeration System in the pulp and paper industry

- Seperation via Aeration

- Neutralization

- Emergency Tank

- Storage and Equilization

- Hydrolysis

- Pre-Acidification

- Stripping

- Sulfur Oxidation

- Selector

- Carbon Removal

- High Loaded MBBR

- C02 Stripping / Lime Trap

In addition to setting an optimal pH value, the selection of a suitable stirrer is also essential for a successful precipitation reaction. For the destabilization of the colloidal state, a high energy input and a long contact time between the precipitating agent and the colloid are required to form microflakes.

The INVENT CYBERPITCH®-Mixer combines these aspects with its flow-optimized agitator blade shape and its design for high speeds.

The INVENT GRF-Mixer is ideal for alternative agitator blade shapes.

In the case of a low-gravity agitator design, the INVENT HYPERCLASSIC®-Mixer is suitable.

Crucial for the success of the development of Markoflocking is a flock-gentle stirring, with simultaneous complete circulation of the entire tank content and the flocculation aids within the dwell time.

The INVENT HYPERCLASSIC®-Mixer has low shear forces due to its hyperboloidal agitator body shape and low speeds and at the same time ensures complete mixing of the container. This leads to frequent particle interactions, which enables maximum floc growth.

In the case of drinking water reservoirs that are not continuously mixed, there is a risk of temperature stratification (thermal stratification) and thus post-contamination and algae formation. In addition, zones of increased concentration of chemicals (disinfectants) can occur, from which toxic substances that are hazardous to health can form.

The NSF-certified INVENT HYPERMIX®-Agitator was specially designed for this application, ensures complete, efficient circulation and prevents layer formation and is manufactured in its entirety according to hygienic design guidelines (according to DIN EN 1672-2:2009-07).

Depending on the application, the INVENT HYPERCLASSIC®-Mixer is also used.

INVENT HYPERCLASSIC®-Mixer

In hydrolysis, complex macromolecules such as carbohydrates, proteins and fats are broken down into shorter organic compounds with the help of enzymes that act as biological catalysts.

The HYPERCLASSIC®-Mixer impresses above all with its low-shear energy input and at the same time offers optimal homogenization of the tank contents. In addition, the flow speed on the water surface is reduced to such an extent that no oxygen is introduced.

INVENT HYPERCLASSIC®-Mixer

A sufficient initial acidification of the dissolved polymers to form short-chain organic acids is decisive for a stable and efficient process in anaerobic wastewater treatment and ultimately a high methane yield.

Since this process is carried out by anaerobic bacteria, it is essential to avoid oxygenation, for example via the water surface.

The INVENT HYPERCLASSIC®-Mixer is installed near the bottom and generates a strong radial bottom flow. Since the speed at the water surface has reduced to such an extent that oxygen entry is effectively prevented, the INVENT HYPERCLASSIC®-Mixer is particularly suitable for this agitating task. In addition, thanks to the high pumping capacity, it ensures that all of the wastewater is thoroughly mixed, thereby ensuring efficient utilization of the entire reactor.