INVENT made a major contribution by introducing hyperboloid mixing technology to the water and wastewater treatment market in the 1990s.

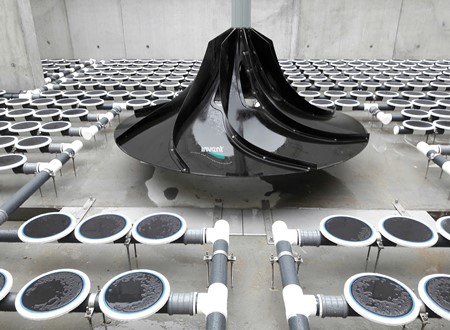

HYPERCLASSIC®-Mixer

Product Information

The HYPERCLASSIC®-Mixer is the optimum mixer for all suspending and homogenization tasks required for water and wastewater treatment.

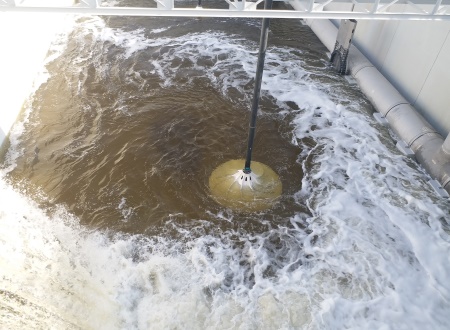

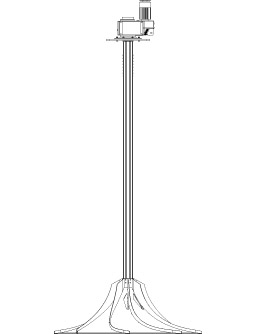

The rotation of the hyperboloid-shaped agitator body close to the bottom generates high-speed and turbulence at the bottom of the basin. This reliably prevents the settling of sludge particles.

Eight transport ribs generate a three-dimensional main flow with a high circulation rate. This ensures excellent, uniform mixing.

Because of the low speeds, the energy input is low in shear force. Sludge flocculation is thus subjected mechanically to minimal stress loads.

Low speed at the water surface reliably prevents aerosol formation and oxygen transfer.

Efficient design and the use of rugged materials minimize operating and maintenance costs.

| Designation | Value |

| Rated Capacity | 0,37 kW – 37 kW |

| Mixer Body Diameter | 500 mm – 2.500 mm |

| Rotation Speed | 14 rpm – 40 rpm |

| Direction of Rotation | Clockwise or Counterclockwise |

| Mixer Body Material | Glass fiber reinforced plastic or high-tech polymer |

| Shaft Material | Glass fiber reinforced plastic or stainless steel |

| Weight | 50 kg – 1.200 kg |

| Efficiency Class | IE3 |

DC Water Blue Plains, USA

Plant: WWTP DC Water Blue Plains, USA

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2013

Application:

- Suspension and Homogenization for Denitrification in anoxic basins

Scope of Delivery:

New York City, USA

Plant WWTP Bowery Bay, USA

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2008

Application:

- Suspension & Homogenization for Denitrification in anoxic Basins

Scope of Delivery:

Murcia, Spain

Plant WWTP Baños y Mendigo, Spain

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2018

Application:

- Mixing for Denitrification in a SBR Tank

- Aeration for BOD/COD-Removal and Nitrification in a SBR Tank

Scope of Delivery:

Schönerlinde, Germany

Plant: WWTP Schönerlinde, Germany

Engineering Office: Berliner Wasser-Betriebe

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 1999

Application:

- Suspension and Homogenization for Bio-P and Denitrification in

anaerobic and anoxic Basins

Scope of delivery:

- 120 HYPERCLASSIC®-Mixer with HYPERPITCH®-Blade

Vienna, Austria

Plant: WWTP Vienna, Austria

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Suspension & Homogenization in for Denitrification in Swing Zones

Scope of Delivery:

Postojna, Slovenia

Plant: WWTP Postojna, Slovenia

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2015

Application:

- Suspension & Homogenization in Intermittent Aerated Tanks

Scope of Delivery:

BorsodChem, Hungary

Plant: WWTP BorsodChem, Hungary

Type of Plant: Industrial Wastewater Treatment Plant – Chemical Industry

Start-up Year: 2007

Application:

- Mixing & Homogenization in SBR Basins

Scope of Delivery:

Jebel Ali, UAE

Plant: WWTP Jebel Ali, UAE

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2009

Application:

- Aeration in the sand trap

- Stirring and homogenization in anoxic tanks

- Stirring and aeration in pre-aeration and aeration tanks

Scope of Delivery:

- Engineering & Design

- 20 HYPERDIVE®-Mixing and Aeration Systems

- 72 HYPERCLASSIC®-Mixing and Aeration Systems

- 32 HYPERCLASSIC®-Mixers

- 160 iCBA®-Aeration Systems

- Installation und Start-up

Kronstadt, Russia

Plant: WWTP Kronshtadt, St. Petersburg, Russia

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2014

Application:

- Mixing in anaerobic and anoxic activated sludge tanks

- Mixing in anoxic/aerobic activated sludge tanks

- Aeration in activated sludge tank

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

In our videos we introduce the INVENT mixing technology

Applications of the INVENT HYPERCLASSIC®-Mixer

Denitrification

With denitrification, it is crucial that the entire tank content is homogenized and that oxygen entry on the surface is avoided. The HYPERCLASSIC®-Mixer is suitable for this, which generates a bottom flow directed radially outwards via transport ribs optimized in terms of flow mechanics. The particles are transported upwards along the pool wall. At the water surface, the speed has reduced to such an extent that no oxygen is introduced.

Precipitation

For the destabilization of the colloidal state, a high energy input and a long contact time between the flocculant and the colloid are required for the formation of micro flocs. The CYBERPITCH®-Mixer combines these aspects with its flow-optimized agitator blade shape and its design for high speeds.

Flocculation

Crucial for the success of the development of Markoflocking is a gentle agitation with simultaneous complete circulation of the entire tank content and the flocculation aids within the dwell time.

The HYPERCLASSIC®-Mixer has low shear forces due to its hyperboloidal agitator body shape and low speeds and at the same time ensures complete mixing of the container. This leads to frequent particle interactions, which enables maximum floc growth.

Neutralization

When conditioning the water, chemicals are added, which should be distributed as quickly and homogeneously as possible in the tank.

If high energy inputs are required, the CYBERPITCH®-Mixer is suitable due to its high speeds and its robust design made of high-quality stainless steel. The INVENT HYPERCLASSIC®-Mixer is used to adjust the pH value and water hardness when energy-efficient mixing of the tank contents is sufficient.

Adsorption

The CYBERPITCH®-Mixer is suitable for quickly and efficiently stirring in the activated carbon and mixing it during the reaction time (adsorption) if a high local energy input is required. The HYPERCLASSIC®-Mixer is used for applications with low shear forces, as it ensures complete mixing that is much more gentle on the particles thanks to the lower speeds, a larger agitator diameter and the design of the agitator body close to the bottom.