INVENT made a major contribution by introducing hyperboloid mixing technology to the water and wastewater treatment market in the 1990s.

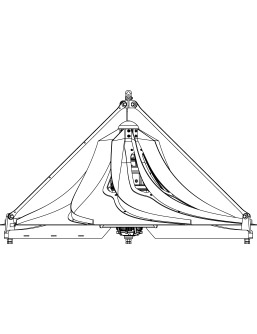

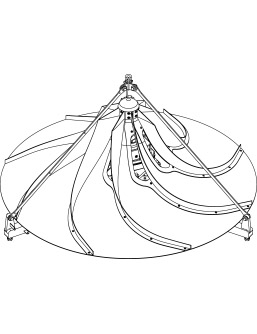

HYPERDIVE®-Mixer

Product Information

The HYPERDIVE®-Mixer is the optimum mixer for all suspending and homogenization tasks required for water and wastewater treatment, especially in very deep basins.

With its hyperboloid mixing system close to the bottom, its fluid mechanical performance characteristics are identical to those of the HYPERCLASSIC®-Mixer.

• High speeds and turbulence on the bottom of the basin

• Prevents settlement of sludge particles

• Three-dimensional main flow with a high circulation rate

• Sludge flocculation is mechanically subjected to minimal stress loads

With a compact, three-legged base, the mixer is ready for operation immediately after being lifted into place – even in filled basins – and connected.

As only well-known drive manufacturers are chosen, no extensive maintenance work is required.

| Designation | Value |

| Rated Capacity | 0,55 kW – 7,5 kW |

Efficiency Class | IE3 |

| Mixer Body Diameter | 2.000 mm , 2.500 mm |

| Rotation Speed | 16 rpm – 42 rpm |

| Direction of Rotation | Clockwise or Counterclockwise |

| Mixer Body Material | High quality, glass fiber reinforced plastic |

| Total Weight | 700 kg – 1.500 kg |

Freudenberg, Germany

Plant: WWTP Freudenberg, Germany

Type of Plant : Industrial Wastewater Treatment Plant – Industrial Park

Start-up Year: 2022

Application:

- Mixing for equalization in homogenization tank

Scope of Delivery:

Neufinsing, Germany

Plant: WWTP Neufinsing, Germany

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Suspension and homogenization for denitrification in anoxic basins

Scope of Delivery:

Erfurt, Germany

Plant: WWTP Develey Erfurt, Germany

Type of Plant : Industrial Wastewater Treatment Plant – Food Industry

Start-up Year: 2015

Application:

- Mixing and aeration for BOD/COD elimination in anoxic basins

Scope of Delivery:

Brüssel, Belgium

Plant: Brüssel, Belgium

Contractor: Groupe Merlin

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2015

Application:

- Suspension and homogenization for denitrification in anaerobic and anoxic basins

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

In our videos we introduce the INVENT mixing technology

Applications of the INVENT HYPERDIVE®-Mixer

Denitrification

With denitrification, it is crucial that the entire tank content is homogenized and that oxygen entry on the surface is avoided. The HYPERCLASSIC®-Mixer is suitable for this, which generates a bottom flow directed radially outwards via transport ribs optimized in terms of flow mechanics. The particles are transported upwards along the pool wall. At the water surface, the speed has reduced to such an extent that no oxygen is introduced.

Precipitation

For the destabilization of the colloidal state, a high energy input and a long contact time between the flocculant and the colloid are required for the formation of micro flocs. The CYBERPITCH®-Mixer combines these aspects with its flow-optimized agitator blade shape and its design for high speeds.

Flocculation

Crucial for the success of the development of Markoflocking is a gentle agitation with simultaneous complete circulation of the entire tank content and the flocculation aids within the dwell time.

The HYPERCLASSIC®-Mixer has low shear forces due to its hyperboloidal agitator body shape and low speeds and at the same time ensures complete mixing of the container. This leads to frequent particle interactions, which enables maximum floc growth.

Adsorption

The CYBERPITCH®-Mixer is suitable for quickly and efficiently stirring in the activated carbon and mixing it during the reaction time (adsorption) if a high local energy input is required. The HYPERCLASSIC®-Mixer is used for applications with low shear forces, as it ensures complete mixing that is much more gentle on the particles thanks to the lower speeds, a larger agitator diameter and the design of the agitator body close to the bottom.