The INVENT TEX-FLEX®-Aeration System with its extremely durable textile membrane specifically for the use in deep basins, as well as for media in which conventional membrane materials are not suitable.

TEX-FLEX®-Aeration System

Product Information

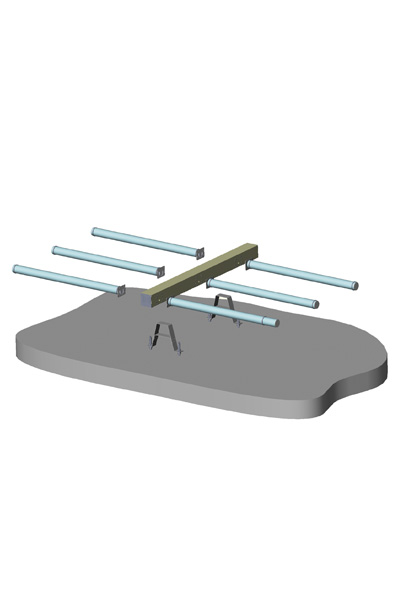

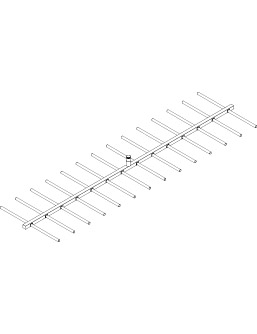

The TEX-FLEX®-Aeration System was especially developed for use in problematic wastewater. It consists of one or more aerator grids connected to the main supply line at the basin edge via a common pipeline.

The combination of a rugged stainless steel body enveloped by a highly resistant textile membrane makes the system perfectly suited for use in deep pools, as well as wastewater contaminated with oil, grease, acids and solvents.

Conventional rubber membranes are typically subject to natural aging and wear. The textile membrane, which is highly resistant to chemicals and heat, provides a reliable alternative.

The system delivers efficient oxygen supply and excellent mixing in the biological stage with minimal pressure drop.

It is low maintenance, quick and easy to install, and can also be produced as a lift-out version. This means that it can be lifted in and out even when the basin is full.

| Designation | Value |

| Amout of Air | 1 – 25 Nm³/h |

Membrane Material | Polyester Fabric |

| Material Support Tube | 1.4301 |

| Material Air Distributor | 1.4301 |

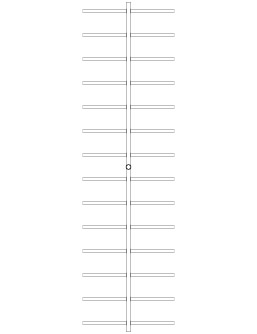

| Diameter Pipe | 60,3 mm |

| Dimensions Air Diffuser | 100 x 100 mm |

| Aktive Membrane Length | 990 mm |

| Bubble Diameter | 3 – 5 mm |

| Pressure Drop | 5 – 20 mbar |

Brasschaat, Belgium

Plant: WWTP Brasschaat, Belgium

Contractor: Aquafin, Belgium

Type of Plant: Municipa Wastewater Treatment Plant

Start-up Year: 2005

Application:

- Aeration of sludge tank for nitrification

Scope of Delivery:

Tønsberg, Norway

Plant: WWTP Exxon Mobile Slagen Refinery, Norway

Contractor: ATEK Avvattningsteknik AB

Type of Plant: Industrial Wastewater Treatment – Refinery Industry

Start-up Year: 2014

Application:

- Aeration for TOC/COD-Removal and Nitrification

Scope of Delivery:

- Engineering & Design

- 180 TEX-FLEX®-Aeration System

- Installation & Start-Up

Fiskeby, Sweden

Plant: WWTP Fiskeby, Sweden

Contractor: ATEK Avvattningsteknik AB

Type of Plant: Industrial Wastewater Treatment

Start-up Year: 2010

Application:

- Aeration for BOD elimination

Scope of Delivery:

Östrand, Sweden

Plant: WWTP SCA Östrand, Sweden

Contractor: ATEK Avvattningsteknik AB

Type of Plant: Industrial Wastewater Treatment – Pulp and Paper Industry

Start-up Year: 2003

Application:

- Aeration in excess sludge tanks

Scope of Delivery:

- 756 TEX-FLEX®-Aeration Systems

- Installation & Start-Up

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

Aeration Systems for Modern Wastewater Treatment

Applications of the INVENT TEX-FLEX®-Aeration System

BOD or COD degradation

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination.

The agitation and gassing system acts as a permanent aeration system for biological carbon degradation in aeration tanks. We can react flexibly to fluctuations in freight. The simultaneous circulation by the agitator ensures a homogeneous and deposit-free mixing even with low air supply in the activated sludge tank.

Aeration in very deep basins

Large water depths limit the area of application of many membrane ventilation systems due to high air temperatures.

Aeration in sludge applications

The iCBA system is the optimal, energy-efficient choice for stabilization operation or to avoid odors in thickened sludge.

Aeration in basins with problematic wastewater

When the use of conventional diaphragm materials is not possible due to the properties of the medium.