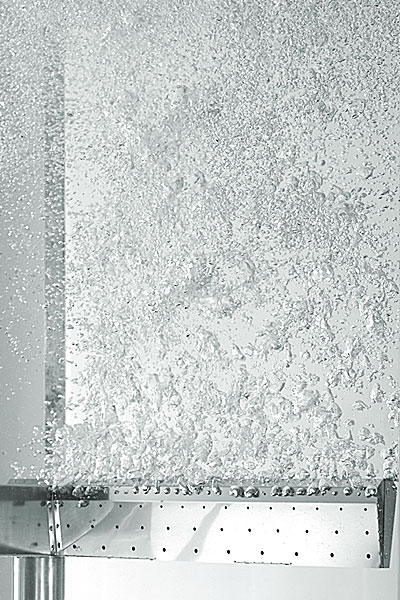

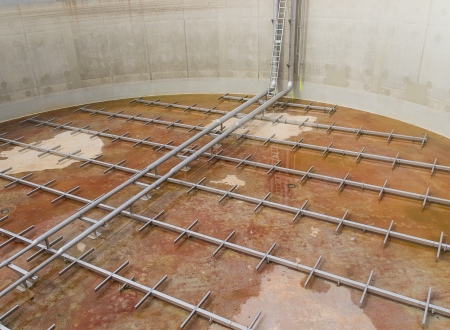

This extremely rugged, coarse-bubble aeration system was especially developed for use in industrial and municipal wastewater treatment plants.

iCBA®-Aeration System

Product Information

With its rugged construction made of stainless steel, the iCBA®-Aeration System is perfect for even the hardest applications in industrial and municipal wastewater treatment plants.

Limitations of conventional membrane aerators, such as high air temperatures or problematic wastewater components, do not restrict the area of application.

Even after many years, the aeration performance is remains constant. The pressure loss of the system remains consistently low.

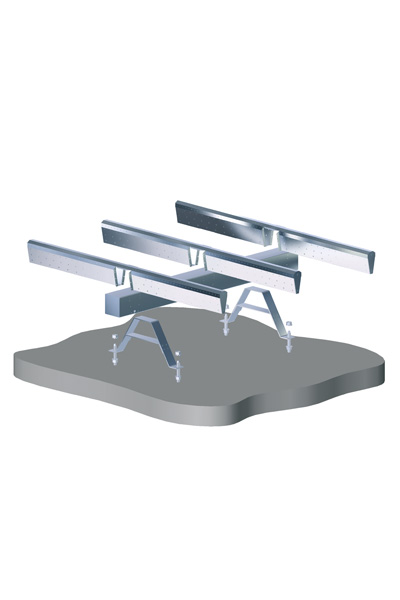

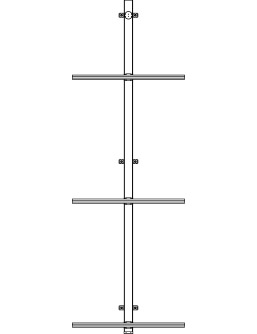

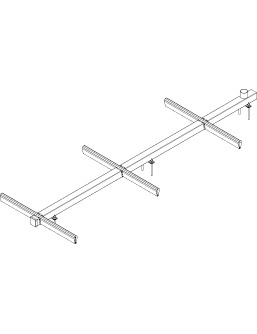

The aeration system consists of the iCBA® aerator element and the bottom distributor on which the individual iCBA® aerator elements are installed at regular intervals.

| Designation | Value |

| Material Air Distributor | 1.4301 / 1.4571 |

Ground Clearance | 50 – 250 mm |

| Dimensions Air Distributor | 100 x 100 mm |

| Material Aeration Element | 1.4301 or 1.4571 |

| Length Aeration Element | 1.300 mm |

| Air Amount | 10 – 100 Nm3/h |

Stendal, Germany

Plant: WWTP Stendal, Germany

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2018

Application:

- Aeration for BOD/COD elimination in MBBR tank

Scope of Delivery:

Landerneau, France

Plant: WWTP U.C.L.A.B. Industrie Landerneau, France

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2016

Application:

- Aeration for BOD/COD elimination in MBBR tank

Lieferumfang:

Plattling, Germany

Plant: WWTP Rheinpapier, Plattling, Germany

Contractor: Stulz-Planaqua GmbH

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2006

Application:

- Aeration for BOD elimination in packing process

Scope of Delivery:

Hallstavik, Sweden

Plant: WWTP Hallstavik, Sweden

Contractor: ATEK Avvattningsteknik AB

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2005

Application:

- Sludge aeration with growth bodies

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

Aeration Systems for Modern Wastewater Treatment

Applications of the INVENT iCBA®-Aeration System

Aeration in packed bed processes MBBR

The mass transfer processes in packed reactors are not determined by the size of the air bubbles, but rather by the nature and volume fraction of growth bodies and their specific surface area and wettability.

BOD or COD degradation

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination.

The agitation and gassing system acts as a permanent aeration system for biological carbon degradation in aeration tanks. We can react flexibly to fluctuations in freight. The simultaneous circulation by the agitator ensures a homogeneous and deposit-free mixing even with low air supply in the activated sludge tank.

Membrane bioreactor (MBR)

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination Continuous cleaning of the membrane surface to limit the cover layer thickness.