With this system, INVENT offers a highly flexible and robust solution for fine-bubble aeration in wastewater lagoons or basins where floor mounting and leveling is not possible.

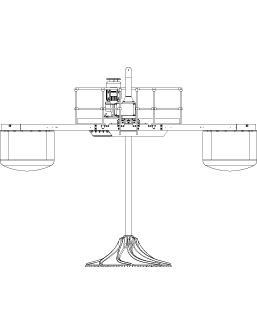

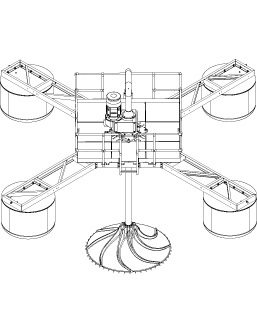

Floating HYPERCLASSIC® Mixing and Aeration System

Product information

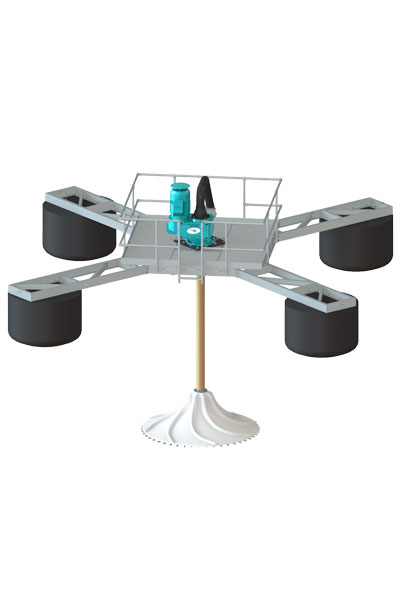

Especially for the use of the HYPERCLASSIC®-Mixing and Aeration System in lagoon treatment systems, INVENT has developed a platform that allows the unique mixer to float smoothly and stably on the water surface.

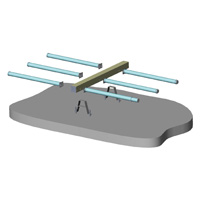

Process air passes through the hollow shaft and hyperboloid-shaped mixer body. This way, near-bottom aeration is achieved without the need for additional installations in the lagoon.

Even previously unused sections of the lagoon can be accessed with the floating version of the HYPERCLASSIC®-Mixing and Aeration system. Compared to surface aerators, the degree of utilization of the given water volume is significantly higher. Plus, the dwell time is increased by the fluid optimized design of the Evolution 7 mixer.

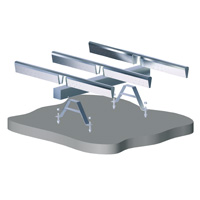

With the slim design of the platform, installation near the lagoon is easy and fast. The complete system is then lifted into the pond, pulled to its operating location and connected. To fix the raft in the desired position, INVENT offers customized weights with guy ropes.

Benefits at a glance:

• Mixing without aeration possible

• Fine-bubble aeration near the bottom of the pond

• Efficient use of the lagoon volume

• Intermittent operation possible

• Floating platform with safety guard rails

The HYPERCLASSIC®-Mixing and Aeration System is tailored to your requirements on a case-by-case basis and can be supplied in a number of versions – an integrated air flow measurement for maximum control or coating options of the platform are possible.

| Designation | Value |

| Rated capacity | 9,2 – 37 kW |

Efficiency class | IE3 |

| Mixer body diameter | 2.000 / 2.500 mm |

| Rotation direction | CW / CCW |

| Rotation speed | 26 – 44 rpm |

| Mixer body material | GfK-PP |

| Cage construction | Stainless Steel |

| Air distribution | HPDE / Stainless Steel |

Lessobo, Sweden

Plant: WWTP Lessobo, Sweden

Type of Plant: Industrial Wastewater Treatment Plant

Start-up Year: 2019

Application:

- Mixing and aeration in lagoon basins

Scope of Delivery:

Iggesund, Sweden

Plant: WWTP Iggesund, Sweden

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2019

Application:

- Mixing and aeration for chlorate reduction in a lagoon

- Mixing for chlorate reduction in a lagoon

- Air-supply

Scope of Delivery:

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

Product videos:

Aeration Systems for modern wastewater treatment

HYPERCLASSIC®-Mixing and Aeration System in the pulp and paper industry

Our aeration products

Applications of the Floating INVENT HYPERCLASSIC®-Mixing and Aeration System

BOD or COD degradation

Highly efficient supply of oxygen to the microorganisms for BOD and nitrogen elimination.

The floating HYPERCLASSIC®-Mixing and Aeration System acts as a permanent aeration system for biological carbon degradation in aeration tanks. It is possible to react flexibly to fluctuations in freight. The simultaneous circulation by the agitator ensures a homogeneous and deposit-free mixing even with low air supply in the activated sludge tank.

Nitrification

The floating HYPERCLASSIC®-Mixing and Aeration System ensures not only optimal mixing in the biological stage but also efficient oxygen supply during nitrification. The mechanical aeration method allows for a high oxygen transfer rate with minimal energy consumption and consistently low pressure loss.

Fakultative aeration

In nitrification stages, the floating HYPERCLASSIC®-Mixing and Aeration System serves as a permanent aerator. If (seasonal) process changes in the activated sludge tank require a temporary changeover from nitrification to denitrification (swing zone), it is possible to run in pure agitation mode without aeration. A change between operation with and without aeration is possible at any time by using the floating HYPERCLASSIC®-Mixing and Aeration System.

Intermittent aeration

By utilizing intermittent aeration in conjunction with modern measurement, control, and regulation technology, the energy consumption of a wastewater treatment plant can be significantly reduced, leading to a stable operation with consistently low effluent values.

The floating HYPERCLASSIC®-Mixing and Aeration System is perfectly suited for intermittent operation as it can easily switch between aeration and mixing modes while ensuring complete mixing of the tank contents in all operational points. The risk of membrane clogging during switched off aeration is eliminated, making the floating HYPERCLASSIC®-Mixing and Aeration System a reliable and efficient choice for wastewater treatment processes.

Aerobe sludge stabilization

Activated sludge with high dry matter content forms a viscous, pseudoplastic medium. Due to the shear-thinning effect of the mixer body of the floating HYPERCLASSIC®-Mixing and Aeration System in aeration mode, there is a significantly better oxygen supply compared to membrane aerators. In addition, problems such as clogging of membranes, pressure increases and material aging due to high temperatures are no longer a problem by using the floating HYPERCLASSIC®-Mixing and Aeration System.

Deammonification

The floating HYPERCLASSIC®-Mixing and Aeration System can be utilized as a continuous aerator to convert ammonium in the sludge water into nitrite under aerobic conditions. When needed, it can easily switch to the mixing mode to increase the proportion of anaerobic bacteria in the Anammox process. Since Anammox bacteria are often sensitive to high or low oxygen concentrations, a highly flexible aerator is desirable. The floating HYPERCLASSIC®-Mixing and Aeration System provides this flexibility, allowing for optimal adaptation to the specific process requirements.