The INVENT iSBR®/iGSR®-System impresses with its customized and intelligent process design and operates using unique and effective machine technology.

iSBR®/iGSR®-System

Product Information

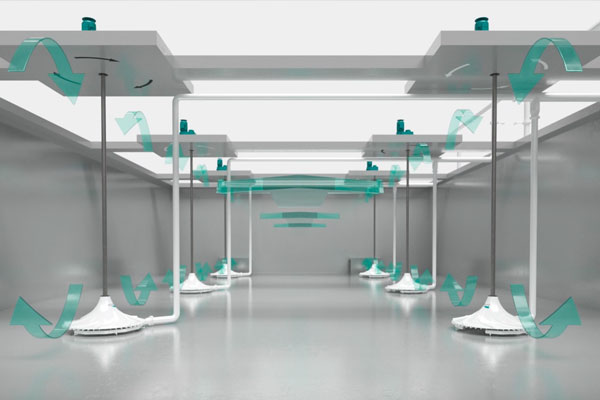

The existing SBR process technology has evolved by INVENT using dynamic simulation models to achieve reliability, energy savings and improved effluent values, and is marketed as INVENT iSBR.

The Sequencing Batch Reactor features its customary batchwise filling (BATCH) and its periodically recurring sequence of process phases (SEQUENCING) in one or more basins (REACTOR). Biological purification of the water and separation of the activated sludge from the treated wastewater all occur in one and the same basin. In most cases, several cycles are run daily. By controlling the inlet and outlet, and by regulating the anaerobic, anoxic and aerobic process phases through agitation and aeration, different purification steps are selectively cycled.

Essential operating conditions, such as complete mixing, effective oxygen transfer and good sedimentation behavior, are ensured by the iSBR concept from INVENT thanks to the use of its proprietary, specialized machine technology.

| Service | Scope of Delivery |

| iSBR-Engineering | Individual process design based on the provided system data or requirements |

| Basins dimensions SBR | |

| R&I Scheme (for INVENT scope of delivery) | |

| Operational strategy (for INVENT scope of delivery) | |

| Air and sewage/sludge line sizing | |

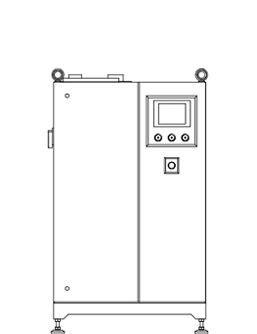

| iSBR – INVENT Machine Technology | iSBR Control |

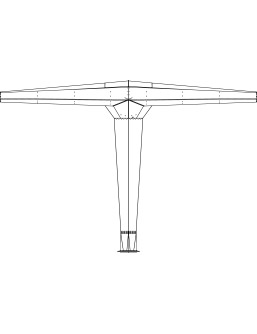

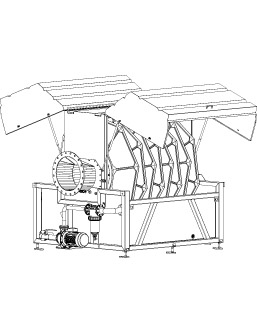

| HYPERCLASSIC®-Mixing and Aeration System | |

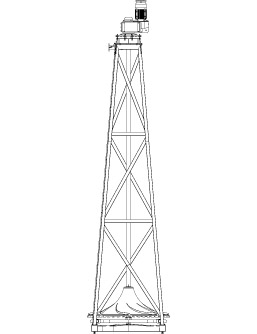

| iDEC®-SBR Decanting System | |

| iTURBO®-Blower | |

| Maximizing Efficiency | iFiLT®-Diamond Filter |

| Fluid Mechanical Optimization | THINK Fluid Dynamix® |

San Miguel de Allende, Mexico

Plant: WWTP San Miguel de Allende, Mexico

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Mixing and aeration for COD elimination, nitrification and denitrification in an SBR plant

- Mixing and suspending in a homogenization basin

- Sludge aeration

- Clear water discharge in an SBR plant

Scope of Delivery:

- iSBR Process Design

- 2 HYPERCLASSIC®-Mixing and Aeration Systems

- 1 HYPERCLASSIC®-Mixer

- 18 iCBA®-Aeration System

- 1 iDEC®-SBR Decanting System

- Installation and Startup

Gabrovo, Bulgaria

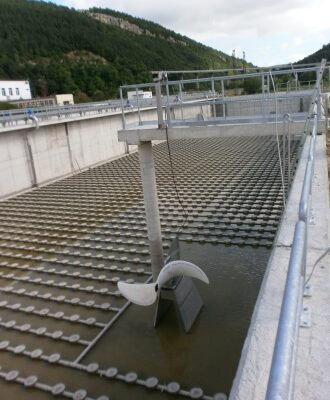

Plant: WWTP Gabrovo, Bulgaria

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2013

Application:

- Mixing and homogenization i anoxic/aerobic rectangular basins

- Intermittent aeration for nitrification and BOD elimination

Scope of Delivery:

- Engineering and Design

- 4 CYBERFLOW®-Accelerators

- 7262 iDISC®-Membrane Diffusers

- 2 iCBA®-Aeration Systems

- 7 HYPERCLASSIC®-Mixers

- Installation and Startup

Holit, Israel

Plant: WWTP Holit, Israel

Type of Plant: Municipal Wastewater Treatment Plant

Start-up Year: 2017

Application:

- Mixing and aeration for BOD elimination, nitrification and denitrification in an SBR plant

- Clear water discharge in an SBR plant

- Suspend and homogenize in sludge storage tank

- Aerobic sludge digestion

Scope of Delivery:

Jacksonville Beach, USA

Plant: WWTP Jacksonville, Florida, USA

Type of Plant: Municipal Wastewater Treatmet Plant

Start-up Year: 2009

Application:

- BOD elimination, nitrification and denitrification in an SBR plant

Scope of Delivery:

- Engineering and Design

- 18 HYPERCLASSIC®-Mixing and Aeration Systems

- 8 iDEC®-SBR Decanting Systems

- 12 E-FLEX®-Aeration Systems

- Installation and Startup

Download product brochure

We would be happy to provide you with the desired document. Please enter your contact details in the form below.

You will then receive a link to the desired document by email.

In this video we introduce our INVENT iSBR®/iGSR®-System

iSBR®/iGSR®-System

The unique INVENT iSBR®/iGSR®-Process allows for aerobic granular sludge production under continuous flow conditions. This is only possible using a cascade of complete mixed stirred tank reactors we create with HYPERCLASSIC®-Mixing and Aeration System and the cyclic process conditions.