Drinking water desalination using INVENT Mixing Technology

INVENT mixers have been used reliably for years for the desalination process of water from the sea in Oman.

Clean water is a scarce commodity, especially in arid, i.e. hot and dry, climatic zones. Affected countries bordering on oceans have a way out of the shortage: desalination of seawater. Worldwide, more than 20,000 seawater desalination plants supply millions of people, plus animals, plants and the adjacent economy with drinking water. Countries in North Africa and Middle East are particularly dependent on this form of freshwater production. The high standard of living on the Arabian Peninsula, for example in Saudi Arabia, the United Arab Emirates, Qatar or Oman, would not be possible without the abundant freshwater extracted from the sea.

Several process technologies are available for seawater desalination. After multi-stage flash evaporation, in which the fresh water is extracted by means of heating and condensation, desalination plants have become established that operate on the principle of reverse osmosis. In this process, saltwater taken from the sea is forced under high pressure through special membranes designed to allow water molecules to pass through, but not larger molecules. The process involves several stages, requiring special mixing systems such as those developed and built by INVENT.

One of the largest seawater desalination plants using INVENT technology is located in the Sultanate of Oman. This seawater desalination plant is located in the north of the oil and gas-rich state, in Al-Ghubra, a suburb of the capital Muscat. The plant has been operating since 2016 and enables the extraction of 191,000 cubic meters of drinking water per day. In operation are 32 HYPERCLASSIC®– and two CYBERPITCH®-Mixers.

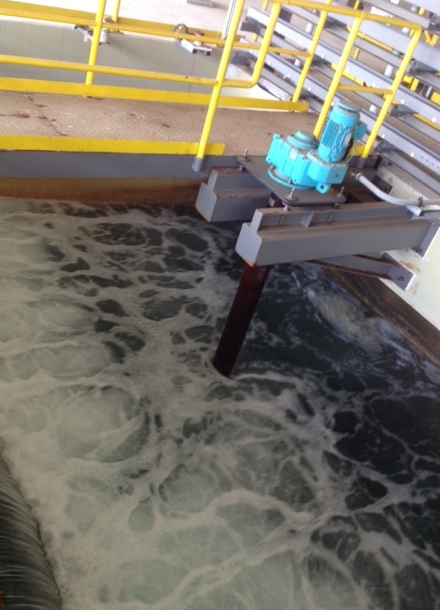

The mixers are integrated in the flocculation process, which serves to separate the finest solid particles. The HYPERCLASSIC®-Mixers with their hyperboloid-shaped mixer bodies ensure particularly gentle suspension and homogenization of the liquid in the flocculation tanks, while the two CYBERPITCH®-Mixers are used for rapid homogenization in the neutralization tanks.

Sustainable seawater desalination will continue to gain in importance in the future, and with it the plants and components required for this purpose. In Al-Ghubra work is currently underway to expand the plant with a production capacity of an additional 300,000 cubic meters of water per day. INVENT will accompany the developments with know-how and commitment and provide innovative products.

For more information, contact our INVENT office in United Arab Emirates:

INVENT Middle East (FZE)

SAIF Office Z3-06

P.O. Box 121720 Sharjah

UAE