Water Reclamation Excellence achieved by INVENT

The Central Valley Water Reclamation Facility (CVWRF) in Salt Lake City will play a pivotal role in the sustainable management of water resources in the region. INVENT is contributing to the facility’s pioneering role by supplying and installing 30 energy-efficient HYPERCLASSIC®-Mixers in the new biological nutrient removal process. This collaboration will position the CVWRF as a beacon of innovation and sustainability in the field of water management.

Nestled in the heart of Central Valley, this state-of-the-art facility demonstrates the commitment of environmental stewardship and water conservation in Salt Lake City. Covering a sprawling area, the facility is equipped with cutting-edge technology designed to treat and reclaim water efficiently. The primary objective is to ensure that water discharged from various sources undergoes rigorous treatment processes, meeting stringent effluent Nitrogen and Phosphorous quality standards before being released back into the environment.

The facility will employ a multi-stage treatment process that begins with the removal of solid particles through screening and sedimentation. Subsequently, advanced biological nutrient removal (BNR) treatment methods will be employed to remove total phosphorus (TP) and total nitrogen (TN), ensuring the effluent will meet the stringent effluent limits set by State of Utah.

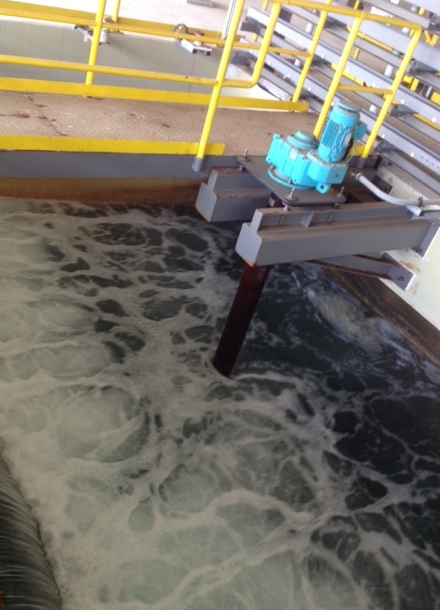

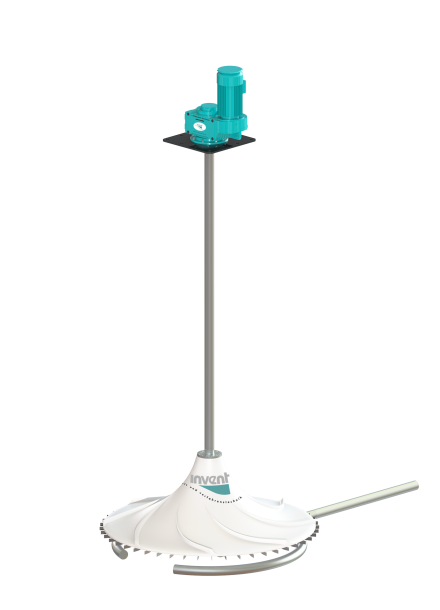

BNR treatment systems are known to have large sections of biological treatment operating with lower oxygen levels (anoxic ) or even without any oxygen (anaerobic). To ensure the biology will remain suspended during these phases, efficient mixing of the wastewater is required. Efforts to maximize energy efficiency and minimize maintenance, Central Valley Water Reclamation Facility plant owners decided to apply the INVENT HYPERCLASSIC®-Mixers for this task.

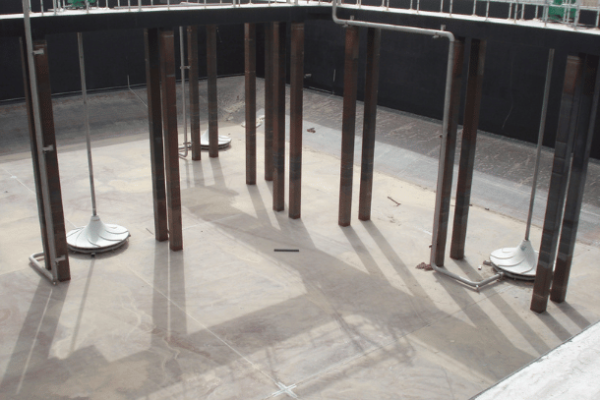

In the Anoxic zones of the newly constructed aeration basins, sixteen of INVENT’s 8ft diameter HYPERCLASSIC®-Mixers evo 7 will be used to keep the biology suspended. Furthermore, twelve mixers will be used to suspend the anaerobic basins, and two will be used to suspend the return activated sludge. Alongside the 30 HYPERCLASSIC®-Mixers evo 7, CVWRF will also have INVENT mixers in their chlorination channel and side stream nutrient removal facility.

During design, INVENT Environmental Technologies Inc. advised CVWRF to use the newest mixer-body design, the HYPERCLASSIC®-Mixer evo 7. The new mixer was introduced to optimize mixing efficiency at even lower energy consumption. The research for this innovative mixer was performed by INVENT and applied modern computational fluid dynamics (CFD modelling) and 3D printing for rapid prototyping. While this new type of mixer is already used on various large plants worldwide, the CVWRF was the first to use this type of mixer in the state of Utah.

In conclusion, the Central Valley Water Reclamation Facility will set a standard for responsible water reclamation practices through its comprehensive biological treatment processes and the implementation of modern energy efficient treatment equipment. In an era where water scarcity is a global concern, the Central Valley Water Reclamation Facility will stand-s as a testament to the power of proactive and environmentally conscious water management.